GIORGIO

Final Project Work

Politecnico di Milano

Project made with:

Davide Mammana

Federico Grilli

Saurabh Verma

2021

Sanitizing shipping box for paintings.

Sanitizing shipping box for paintings.

Giorgio provides a safe shipping for the painting, protecting it from microbiological damages and common shipping-related hazards. Thanks to the cooperation of the Box and the Sanitation Device, the internal area of the box remains a "safe zone" for the entire travel.

Proliferation of bacteria and fungi can damage the pigments, the structures of the painted surface and its support.

To avoid micro-organism attacks, appropriate humidity and temperature conditions must be maintained; the likelihood of these being lacking during transport is very high.

Our product is aimed at transport companies that want to offer to galleries and art museums a safer shipping service for medium-value paintings.

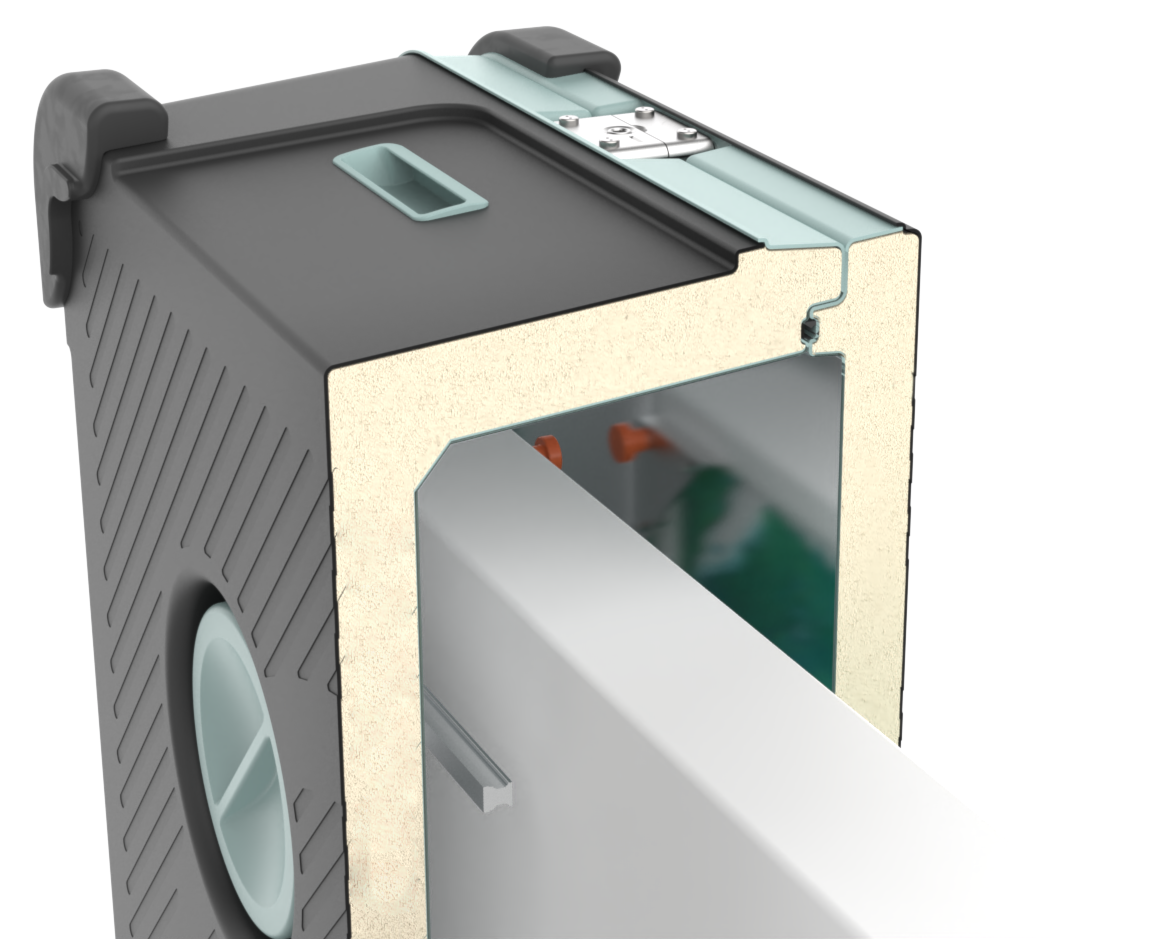

The painting is surrounded by different layers of components. The Fixture System keeps the painting in position, the Box body and the Panel maintain the airtightness, avoiding dangerous hygrometric variations and ensuring protection from shocks. The Caps close and protect the sanitation access when it is not used.

Caps

Panel

Fixture System

Main Body

Internal Layer

UV-stabilyzed ABS

Thermoforming

Support the fixture system and increase the stiffness of the box.

Injected Foam

Low density, closed-cell polyurethane foam

Foaming

Improve the insulation and provide support on both the internal and external layer.

Reflective Layer

PET + Aluminum foils

Reflect the UVC light that doesn’t hit directly the painting.

Rubber Bumpers

Nitrile rubber

Transfer molding

Absorb the impacts on the most fragile points of the box.

External Layer

ABS

Thermoforming

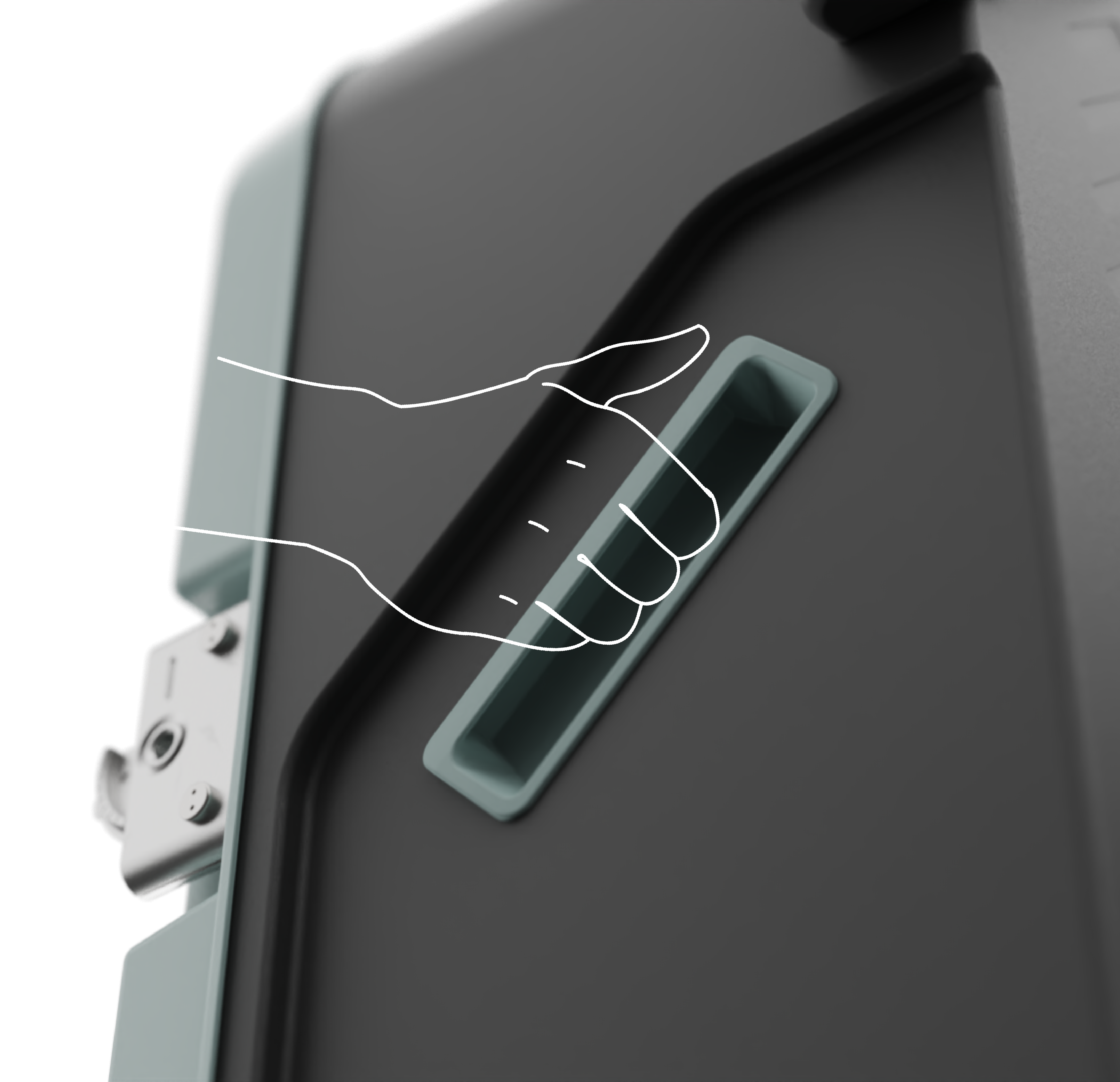

Withstand the external loads, provide grip to handle the product.

Cap

ABS

Twin-sheet thermoforming

Close and protect the access for the UV lamp when not in use.

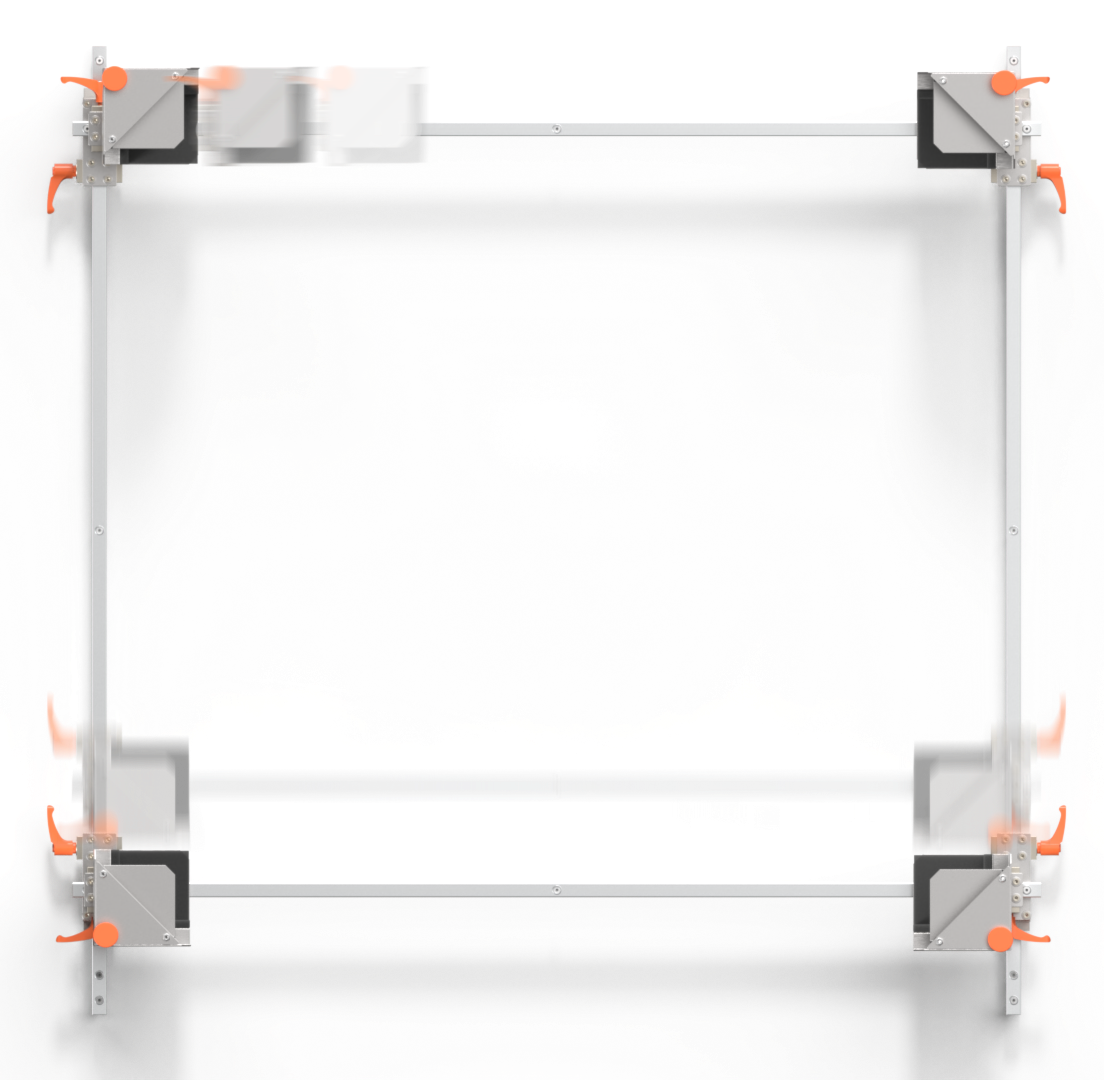

The four clamps, sliding both vertically and horizontally, can easily adapt to different frame sizes. This ensures that every kind of painting can be securely fixed and protected from shocks.

The four clamps, sliding both vertically and horizontally, can easily adapt to different frame sizes. This ensures that every kind of painting can be securely fixed and protected from shocks.

A comfortable hand brake tights the clamp in position. Every clamp can independently be adapted to the frame thickness by rotating the top the knob that opens and closes the two plates. Position and color of Brake and Knob make them accessible and easily recognizable.

The orientation of the handles follows the orientation of the hand and its movement, it helps the passage from the horizontal to vertical position and guides the user in the right orientation of the box.

The draw latches keep the panel in position locking it on every side. To be opened it requires an hex key, an uncommon tool for workers in the shipping chain but that can still be obtained in case of need. These draw latches do not aim to keep the painting inaccessible, but are simply a deterrent for preventing peeking.

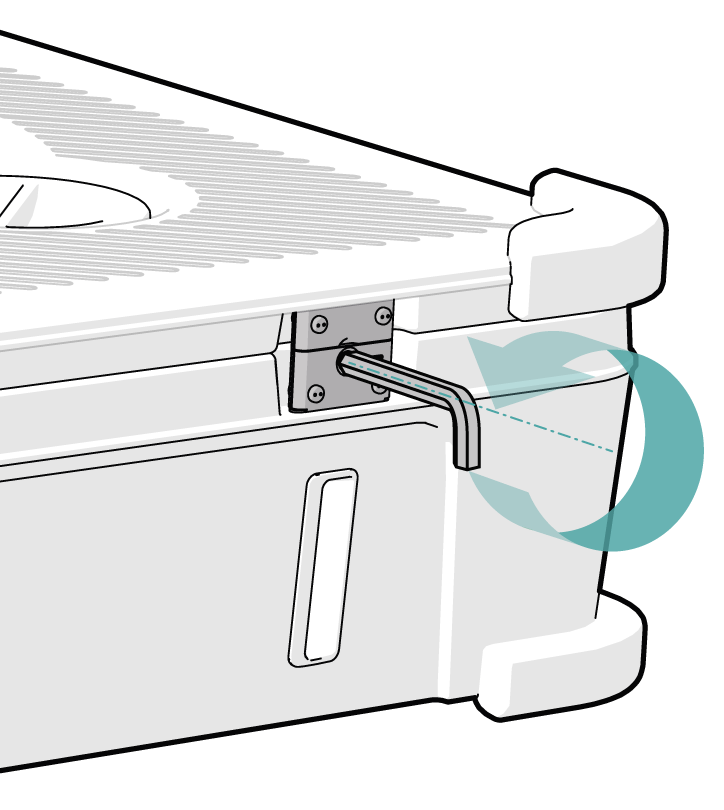

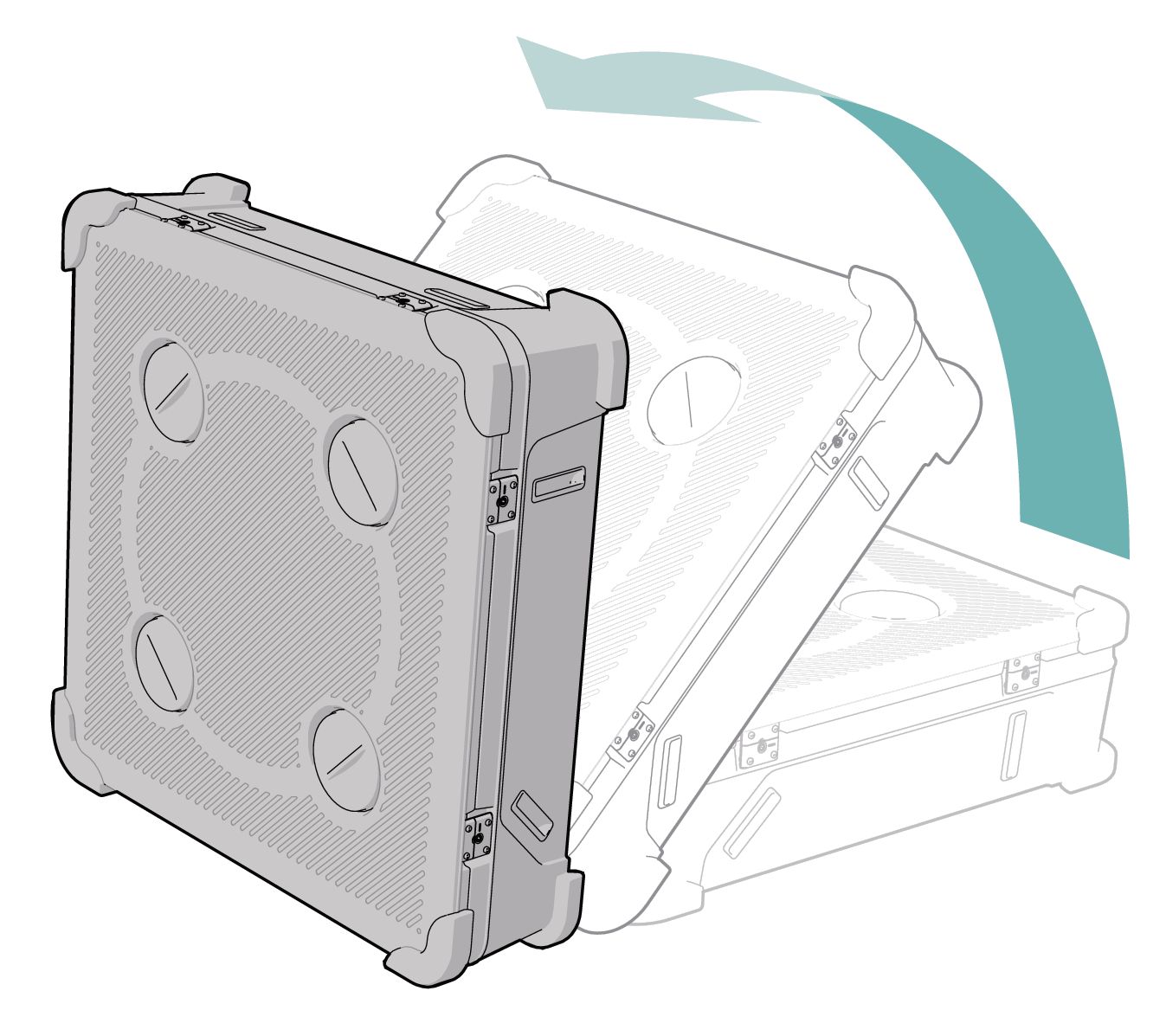

The rubber feet overcome the draft angle of the external layer shell of the box and allow stackability. Thanks to their "L shape", the feet always touch the ground and act as a pivot point during the passage from the horizontal to the vertical position of the box.

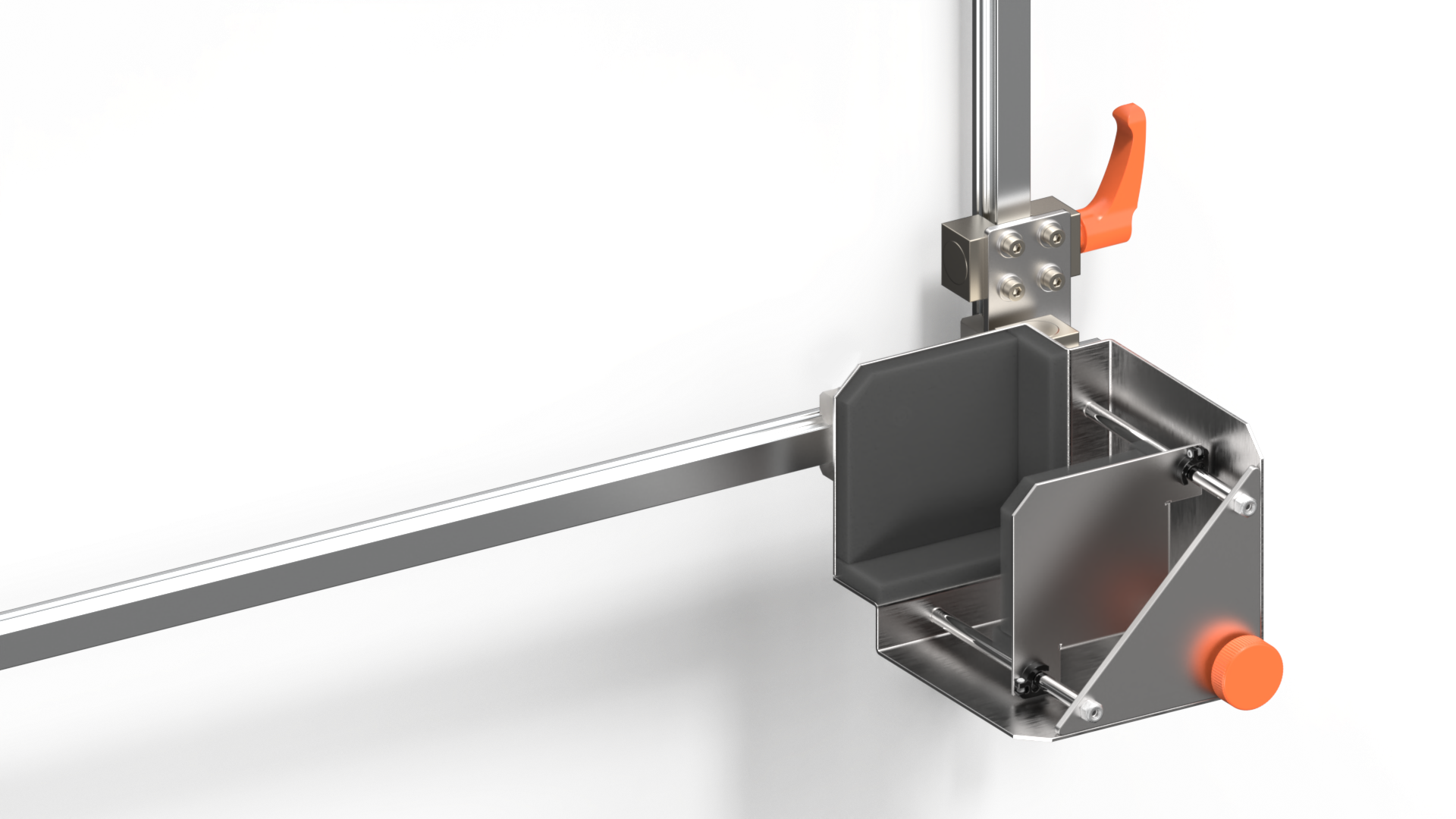

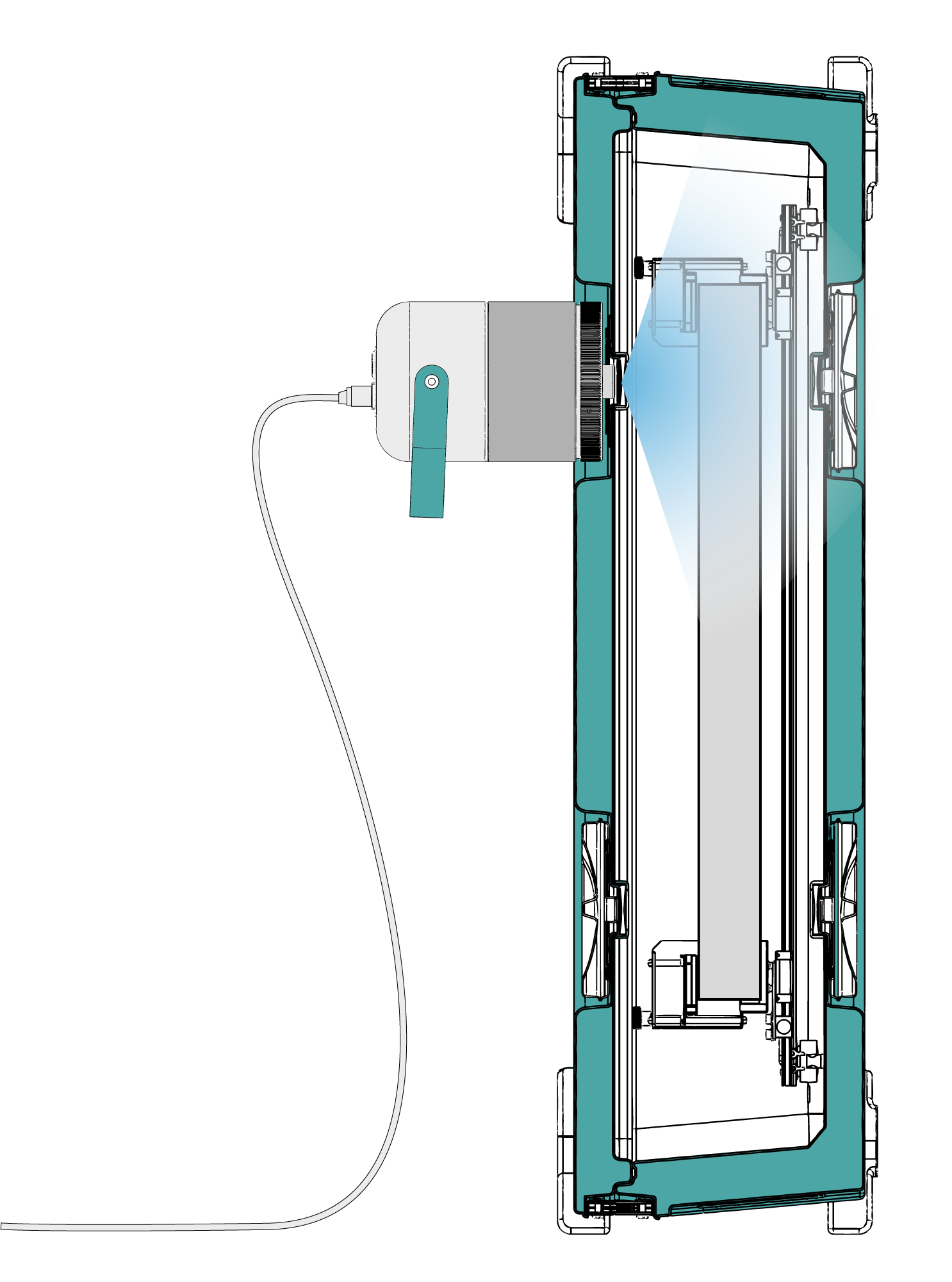

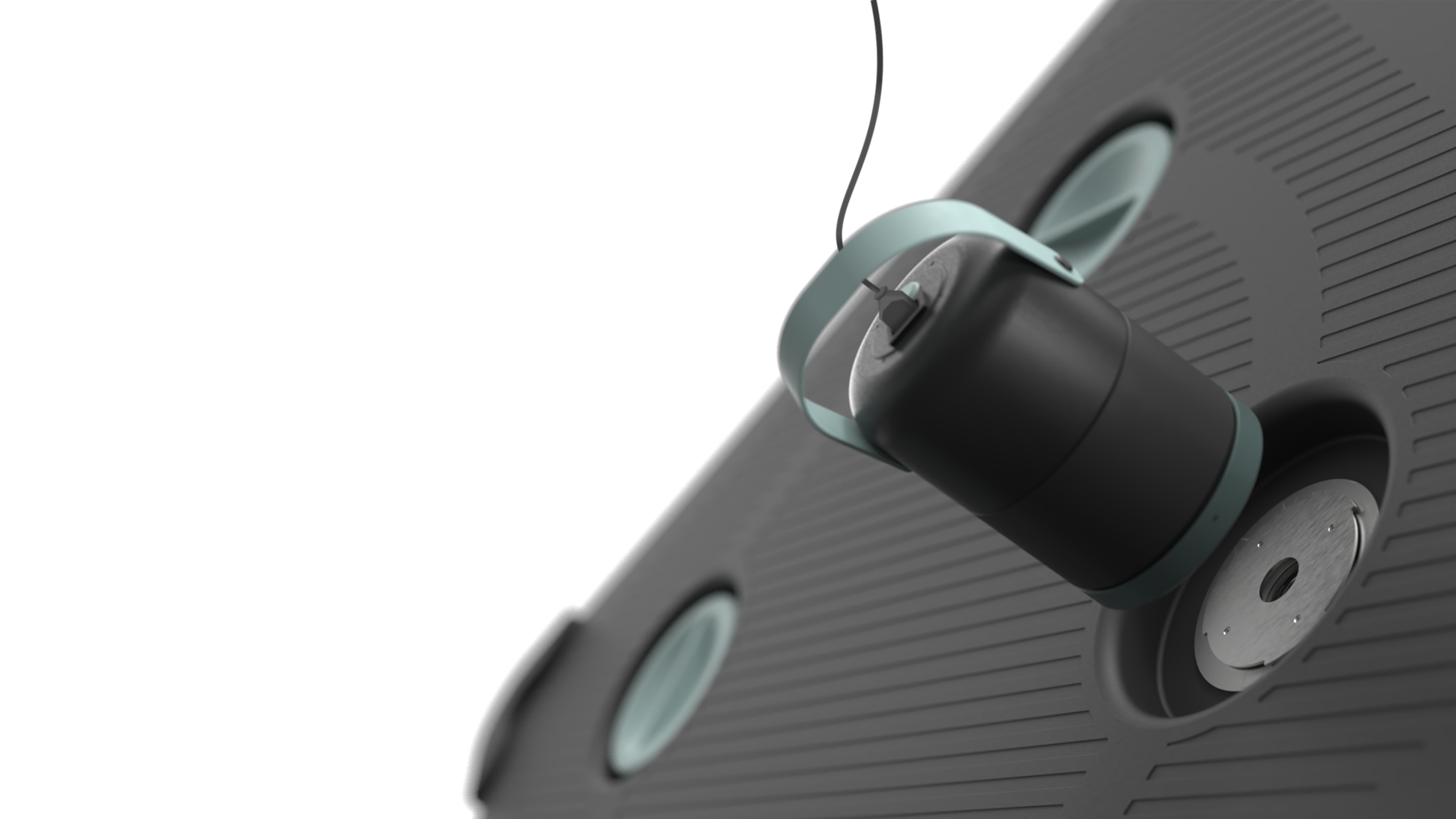

After the painting has been placed and secured inside the box, the sanitisation process can start. The UV-C sanitising lamp is inserted into each slot one at a time. Thanks to the beam angle of 120°, the convex lens and the reflective surface of the box's interior, the UV-C light reaches the entire surface of the painting, its structure and the frame, removing almost the totality of the microorganisms present.

The breech-lock mount guarantees a safe interlock between the lamp and the box, providing a proper access for the pulsed light. The system holds and protect a UV-C transmittant convex lens made of PTFE which enables the passage of light with a wavelength between 100 and 280 nm widening its beam angle while maintaining the interior of the box perfectly sealed. The breech lock mount simply involves the positioning of the device and a further rotation of the ring to fix its position, similar to camera lens mounts..

The sanitation lamp has been developed around the UV-C pulsed light module, which was selected from the catalogue of a well-known manufacturer of sensors and light emitters for special applications.

All the electronic components in the device, involved in controlling the light module, were selected from various catalogues of different manufacturers, while the housing, the rotating gears and some other supports have been designed considering simple and inexpensive sheet metal working processes, ideal for keeping costs low in small batch sizes.

Shell

Handle

Interface

Electronic

Assembly

Silicon

sleeve

Light module

assembly

Cap

GIORGIO

Final Project Work

Politecnico di Milano

Project made with:

Davide Mammana

Federico Grilli

Saurabh Verma

2021